For handlers of all materials that flow, either while being processed or in an end-use, it is important to think about the materials’ flow characteristics. To be brief, viscosity is resistance to flow. With proper installation and an accurate viscosity index, you can be sure to achieve maximum life expectancy and reliable operation of your machinery.Most engineers know what viscosity is, but may have trouble explaining it. It is always a good idea to check the equipment manufacturer’s specifications to determine the proper lubricant and to consider the climate and operating conditions when making your selection. This allows a lubricant to be formulated to meet the original equipment manufacturer’s specifications. You also would see more wear due to film loss.Īdditives can be used to improve the viscosity index.

When the viscosity is too low, greater mechanical friction may occur, which can lead to heavier loads.

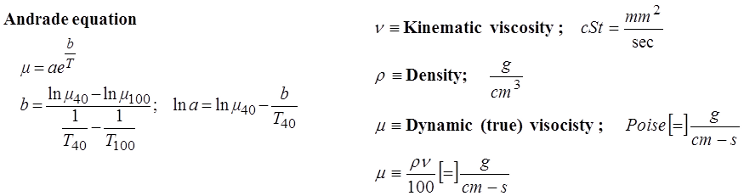

Keep in mind that a slight difference in temperature can equate to a huge viscosity change that could be detrimental to the asset.įor example, if the viscosity is too high, it could result in low oil flow, causing oil starvation and dry startups. Some oils may have the right viscosity at certain temperatures but do not quite meet the needs of both ends of the temperature range. A higher VI is more desirable because it enables the lubricant to provide a more stable lubricating film over a wider temperature range. If drawn on a chart with viscosity on a vertical axis and the temperature on a horizontal axis, the slope would be more horizontal with higher viscosity indexes. A higher number means the lubricant changes viscosity at a lower rate based on the temperature. Highly refined mineral oils have a VI of approximately 120. While the VI has no units of measure, it is well known that the viscosity index of a conventional mineral oil is between 95 to 100. This is then compared to a scale based on two reference oils. To determine an oil’s VI, the viscosity is measured at two temperatures: 40 degrees C and 100 degrees C. Understanding VI is important to discern whether the lubricant in question meets the asset’s requirements based on the operating temperature range. The change in an oil’s viscosity due to a temperature change is called the viscosity index (VI). The lubricant’s formulation and quality will impact how much its viscosity will drop with an increase in temperature. Viscosity is also affected by temperature. Taking a proactive approach to monitoring your lubricant’s viscosity can make a big difference in the health and life of your machinery. It is influenced by several factors such as contamination with water, particles or other lubricants. Viscosity can be defined as an oil’s resistance to flow and shear. A lubricant’s viscosity is its most important property.

0 kommentar(er)

0 kommentar(er)